Assembly

We’ll See Your Part Through All Required Sub-Assembly Processes

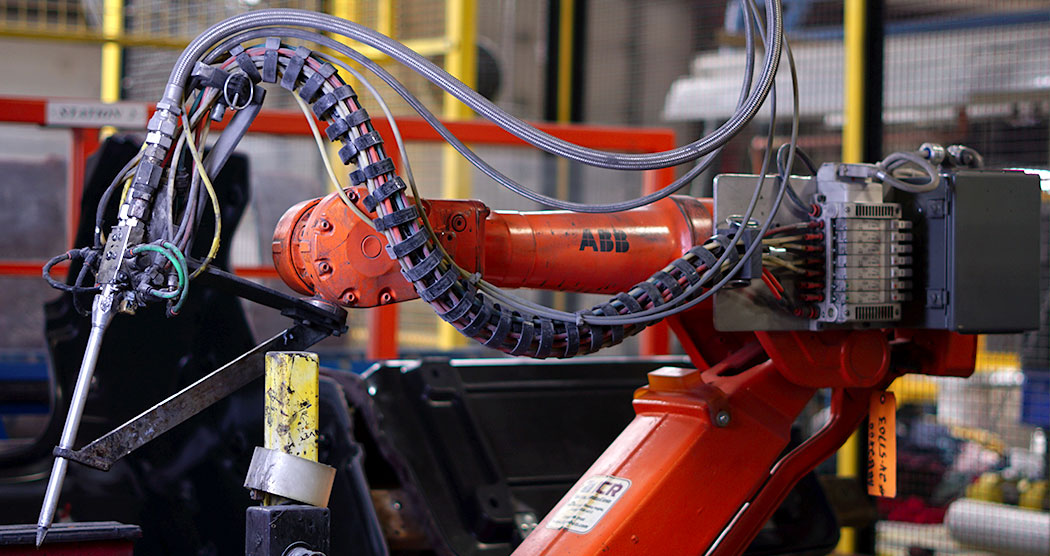

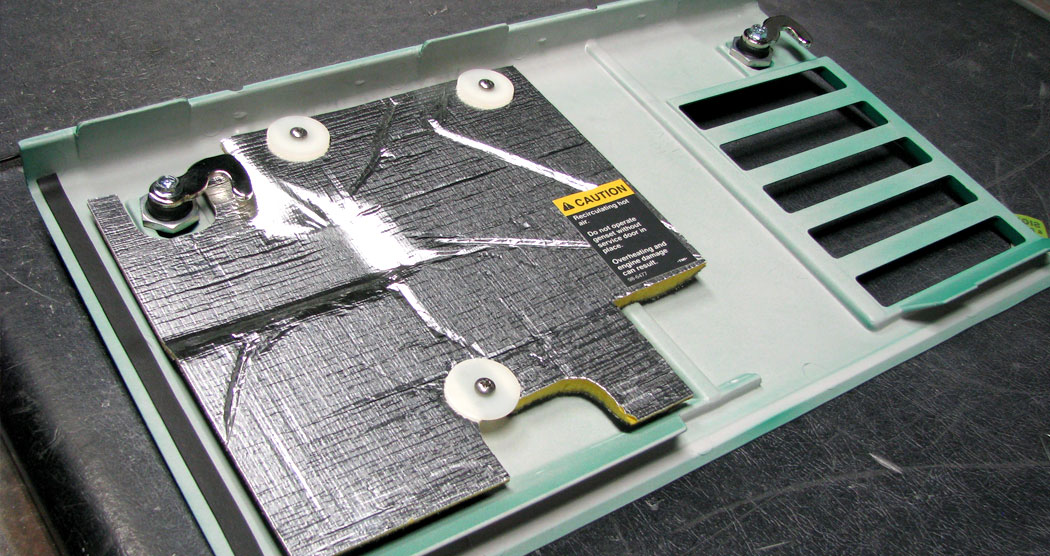

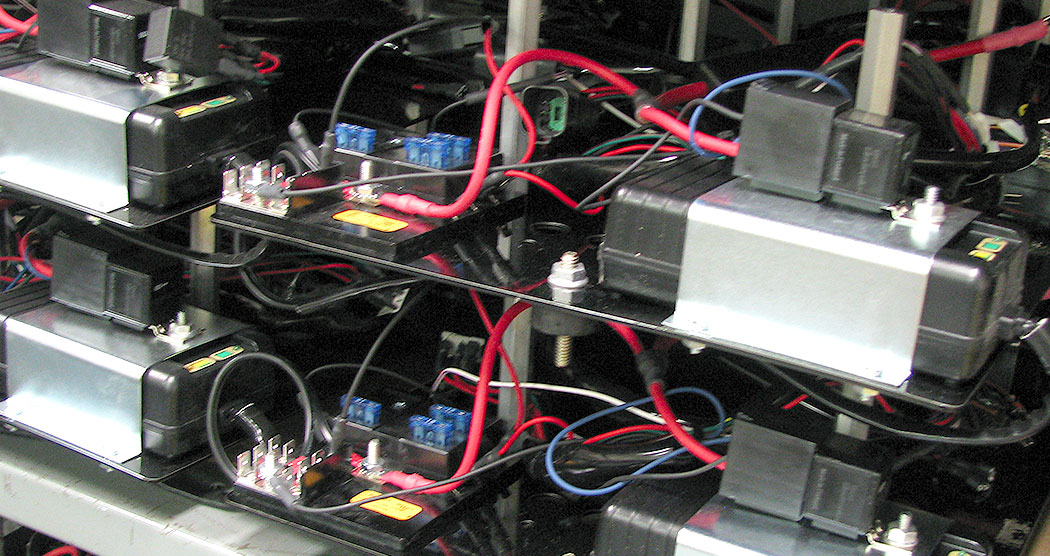

MasterMold’s team of expert engineers can see your part through any required sub-assembly processes so upon your receipt of the part it can be removed from the packaging and put into your application without any additional handling, cost and floor space in your facility. With trained on-site staff and the use of collaborative robotics, MasterMold can apply product seals, complete sub-assemblies such as hinges and switches as well wire harnesses. Upon completion of the assembly, our final inspection process can include product testing and function.

With trained on-site staff and the use of collaborative robotics, MasterMold can apply product seals, complete sub-assemblies such as hinges and switches as well wire harnesses.

Inventory Control

MasterMold use of an electronic inventory control through their RFID system ensures that every purchased component and manufactured component is traced throughout the manufacturing process. From incoming to outbound shipments this system automatically monitors the level of inventory to help protect you against product shortages and controls product cost by managing the proper inventory levels to meet your demands.

RFID

As your part travels through the final processes, the RFID system will allow us to see what cells your product traveled through, operators that inspected the parts and even what parts were on the outbound shipment as loaded into the transport trailer.

Tier 2 Sourcing

MasterMold’s team of engineers and purchasing agents will work with you to locate the best designed, best price and highest quality parts sourced from dependable companies with good reputations to meet the needs of your parts ensuring your finish parts arrive on time and to your standards.

MasterMold’s in-depth quality process will drive best practices and quality insurance to the tier suppliers used to manufacture your parts. From on-site inspection of Tier 2 processes and capabilities to in-depth incoming receiving inspection upon receipt before those components ever reach the manufacturing process.

Request a Factory Tour

Would you like a factory tour of any of our facilities? Contact us by either filling out the online contact form or calling our headquarters in Johnson Creek, WI: (920) 699-2711.