Quality & Sustainability

Shaped by Our Commitment to Quality

Our company has a simple, but a meaningful quality statement: “Make Our Customers Happy and Continue To Improve”.

MasterMold applies the best practices and principles to its processes, ensuring the highest quality standards are always followed and measured.

We maintain the philosophy that “quality” starts with each and every employee at MasterMold. From incoming receiving inspection to the final outbound inspection, quality is measured at each and every step of the process. MasterMold is ISO 9001:2015 Certified.

RFID Traceability

MasterMold uses a sophisticated custom-designed RFID (radio frequency identification) system, which allows for full traceability and process improvement to your part quality. The RFID system will allow an ID tag to be molded into your part or post applied. This ID tag will identify every single process – from molding through paint, along with all the various operating parameters in each of those processes – for each specific part manufactured, helping to reduce costs where applicable.

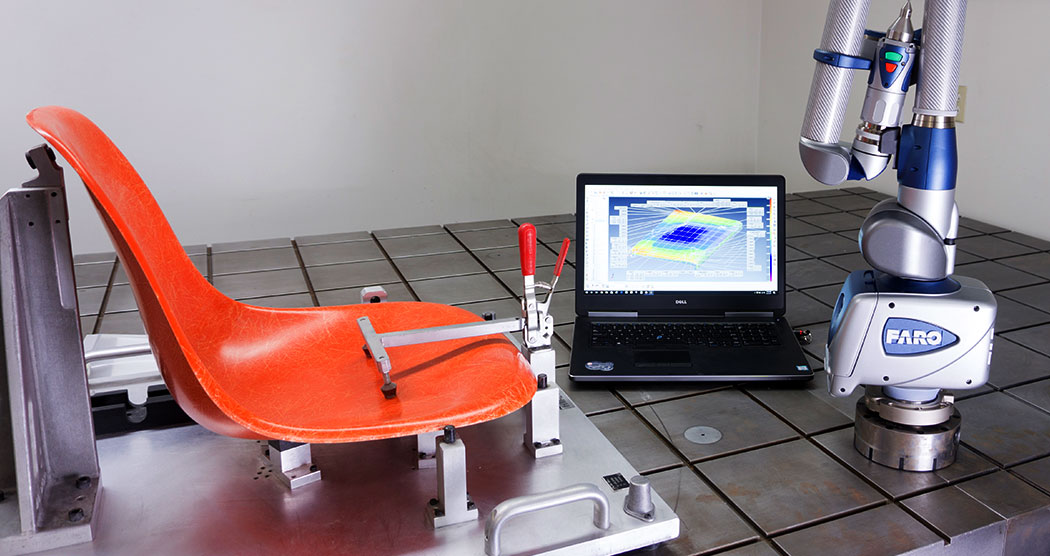

In addition to the RFID system, MasterMold uses a multitude of quality tools to ensure that each and every part is manufactured to your specifications. With the use of robotic vision and inspection, MasterMold can ensure each part is molded with the features and hardware each and every cycle. Final molded parts can be exacted with the most advanced 3D measurement solutions of both large and small parts from FARO.

Sustainability

MasterMold’s longevity and prosperity can be linked to its focus on 3 core areas of sustainability: Build a company that has strong economic longevity, drive positive changes to the environment, and focus on people and the generations that will follow.

Reduce cost, reduce risk and increase revenue while building its brand.

Environmental Focus

Reduce energy consumption and emissions, look for ways to lower our carbon footprint, minimize waste, use recycle or renewable resources whenever possible.

Social Focus

Improve the communities where we work and live through outreach programs and supporting local organizations that drive a positive impact. Place emphasis on employee health, safety, and well being along with the education of its workforce in the ways they can improve the world we live in.

With any new program, MasterMold will always design for sustainability using life cycle analysis. MasterMold wants to see our world grow in a positive manner so generations that follow can be proud.

Inventory Control

Inventory control covers all possible processes involved in the flow of goods from manufacturing to customers, including manufacturing, distribution, and transportation. RFID has become a revolutionary element in supply chain management. RFID ensures that the right goods are available in the right place with no discrepancies and zero errors. Purchased components, raw materials, and manufactured parts are tracked with the reader ID tags that provide real-time information to ensure everything is readily available. This makes the supply chain considerably more robust and precise because it improves the efficiency and reliability of the complete chain thus reducing cost.

Request a Factory Tour

Would you like a factory tour of any of our facilities? Contact us by either filling out the online contact form or calling our headquarters in Johnson Creek, WI: (920) 699-2711.